Antioxidant 168

Antioxidant 168

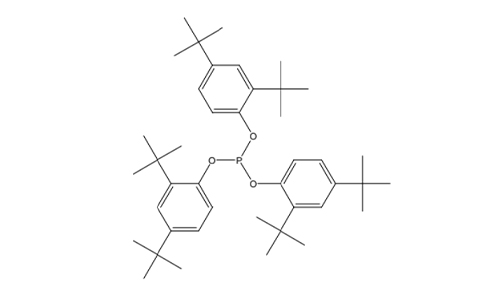

| Cas No. | 31570-04-4 |

|---|---|

| Chemical Name | Tris(2,4-di-tert-butylphenyl) phosphite |

Introduction & Specs

| Introduction | Antioxidant 168 is a hydrolytically stable phosphite processing stabilizer. It acts as a secondary antioxidant during plastic processing and protects the polymer matrix by reacting with the hydroperoxides formed at this stage by auto-oxidation. The combination of Antioxidant 168 with primary antioxidants provides a synergistic stabilization activity, preventing the overall thermo-oxidative degradation of the material. |

| Benefits | Antioxidant 168 is an organo-phosphite of low volatility and can be used at high processing temperature. It is particularly resistant to hydrolysis. l Antioxidant 168 protects polymers that are prone to oxidation during pelletizing, compounding, converting, recycling, as well as any processing step exposing the matrix to oxygen, high temperature and mechanical stress. l It prevents molecular weight changes in the material triggered by the degradation processes such as chain scission (dominant in case of PP) and cross linking (dominant in the case of LDPE). l It also contributes to reducing discoloration effects such as yellowing or pinking. l Antioxidant 168 blends with other primary antioxidants (Antioxidant 1010 and Antioxidant 1076) have very good synergetic effects for polymer stability. |

| Application | Antioxidant 168 is a hydrolytically stable phosphite processing stabilizer. As a secondary antioxidant, it protects the polymer, in particular during the early stages of the processing step where oxygen, high temperature and mechanical stress trigger the formation of hydro-peroxide species responsible for degradation. Antioxidant 168 reacts with hydro-peroxides to yield non-radical harmless products and is therefore called hydroperoxide decomposer. As a secondary antioxidant, Antioxidant 168 can be combined with primary antioxidants such as Antioxidant 1010 or Antioxidant 1076 providing a synergistic blend for applications in polyolefins or olefin-copolymers such as HDPE, LLDPE, PP, EVA, as well as PC, PA. These types of blends can also be used in engineering plastics such as PBT, PET and styrenic elastomers like PS, ABS, BR, SBS as well as tackifier resins and adhesives. |

| Guidelines for Use | Recommended loading concentrations of Antioxidant 168 range between 0.05% and 0.2% combined with appropriate levels of other additives required for a proper processing stabilization of polymers. |

Sales Specification

| ITEMS | Standard Specification |

| Appearance | White powder or granule |

| Melting Point | 183.0-187.0℃ |

| Acid Value | 0.3 mg KOH/g max |

| Transmittance | 425nm ≥98.0 |

| 500nm ≥98.0 | |

| Anti–hydrolysis performance | Qualified |

| Heating loss | 0.30% max |

| Main content | 99.0% min |

| 2,4-di-tert-butylphenol | 0.20%max |

| Packing | Available in 25KGS/Bag, etc. |

| Storage | Keep away from moisture and sunlight and store separately from strong acids, strong alkalis and strong oxidants |

| Shelf Life | 12 months from production date. |

aton@predawnchem.com

With cooperation with domestic academy of sciences and many institutes, our plant is equipped with ....